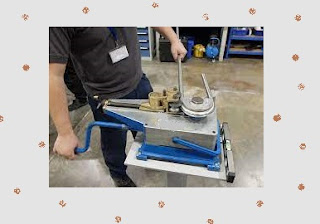

Do you ever find yourself wishing that you could build intricate bends in metal pipes and other materials for use in your personal projects or in industrial applications? Should this be the case, the ideal approach would be to use a heavy-duty pipe bending machine. When you purchase these powerful machines from pipe bending machines manufacturers, it is possible to bend metal pipes into complicated patterns that would normally be difficult to achieve without the use of specialist hand tools or welding equipment.

The

article goes on to detail the many applications that such a machine may be used

for, as well as the advantages and things to take care of related to its use.

Advantages Of Pipe Bending Machines

· In its most basic form, a pipe bending machine is a forming machine tool, and its primary function is to assemble a bend on a work piece. For the purpose of producing a bend, it makes use of a motion that is both linear and rotational. When it comes to bending reinforcing bars, this particular sort of equipment is not only long-lasting but also quick, efficient, and cost-effective.

· It may be used for a variety of bar configurations, including circular bars and busbar bars. A round bending machine is another name for this kind of equipment. In addition to having a large production capacity, it is an important piece of machinery that every steelyard must have.

· Additionally, the usage of these devices does not call for any specialized knowledge or abilities on the user's part.

· A semi-automatic hydraulic pipe bender is a flexible and dependable tool that is preferred by many experts in sectors such as construction, plumbing, and automotive. It has the capability to handle a broad range of pipe sizes and thicknesses, making it an ideal choice for these professions.

Safety Considerations When Operating A Pipe Bending Machine

1. When you are getting ready to unleash the full power of your pipe bending machine, it is very necessary to put safety ahead of anything else possible. In the event that it is not controlled with prudence, a machine that is capable of bending pipes with precision and accuracy may also be a force that does not want to be ignored. Even the smallest mistake or error in judgment may result in injuries of a severe kind, damage to equipment, and even expensive downtime.

2. When operating your pipe bending machine, it is very necessary to adopt a very careful and cautious attitude to safety in order to prevent a disaster of this kind. To achieve this, it is necessary to ensure that the working space is clean and has enough ventilation, to wear the required personal protection equipment (PPE), which includes safety glasses, gloves, and a dust mask, and to strictly adhere to the rules provided by the manufacturer.

3. In addition to this, it is of the utmost importance to keep the workstation clean and well-organized, ensuring that the area around the machine is free of any obstacles or potential trip hazards. Additionally, it is necessary to do routine inspections of the equipment and the environment in which it is situated in order to detect and eliminate any possible dangers before they become an issue.

By adhering to these simple but essential measures, you will be able to guarantee a secure and effective functioning of your pipe bending machine. This will enable you to concentrate on what is most important, which is the production of pipes of superior quality and the realization of your pipe ambitions.

Bottom

line

If

you've ever dreamed of taking your pipe fabrication business to the next level,

we hope you've found our guide to unlocking the power of a pipe bending machine

to be a game-changer. With the right techniques and tools, you can transform

your pipe dreams into reality.